About industrial temperature sensors

General about industrial temperature sensors

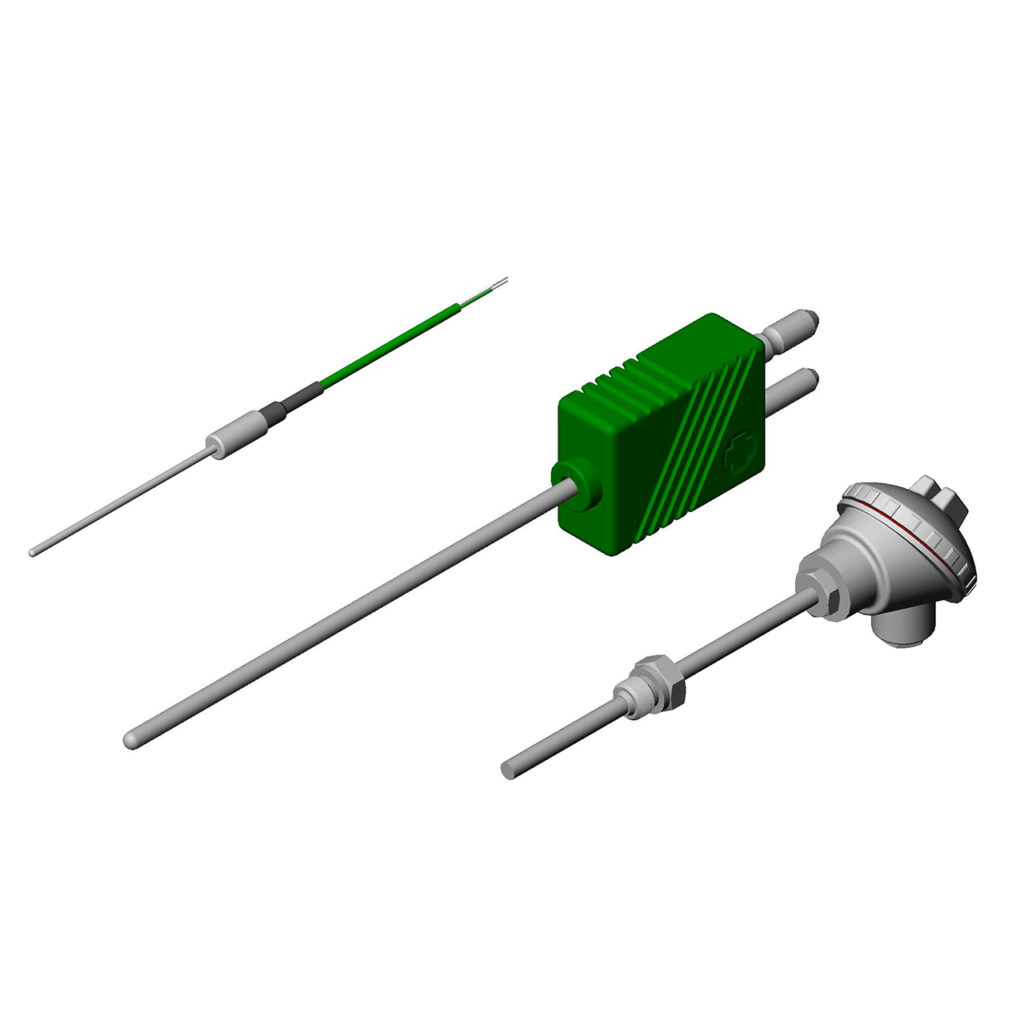

Platinum resistance thermometers (Pt100/Pt1000) and thermocouples are the most commonly used sensor types. We have a large selection of sensor models directly available for delivery and suitable for many applications.

Naturally there is a range of sensors tailored for special demands and our skilled technicians and competent workshop with great capability are always prepared to help you with sensor constructions that suit your requirements whether you work as OEM, in a process industry or in a development laboratory.

As a complement to Pt100-sensors and thermocouples can non-contact measurement with IR-pyrometers be an alternative. Examples of advantageous non-contact measurements can be moving or live electric objects or very high temperatures.

Thermocouples

Thermocouples are standardized according to the IEC60584 into eight letter designated types: E, J, K, N, T, R, S, B. In modern industry the types K and N are the commonly used followed by the noble metal types S, R and B. The thermocouple types E, J and T are today often replaced by the types K and N as well as Pt100-sensors.

In 2013 the standard IEC 60584 was completed with thermocouples type C and A, of which both contains different combinations of the elements Tungsten and Rhenium. These are both intended for very high temperatures, up to 2500 °C mainly in vaccuum environments.

The mineral-oxide insulated, metal-sheathed (MIMS) thermocouples K and N are very rigid and robust. Depending on dimensions (mainly diameter) and life-time requirements they can be used in temperatures up to 1000 to 1200 °C.

A great selection of cables, connectors, panels and other accessories easing correct connection of sensors are available by Pentronic. Correct connections are important to make measurement chains work properly.

- Products:

- You can find our Thermocouple Sensors on our product page: Temperature sensors

- Handling: Advice for handling temperature sensors can be found in our information sheet Instructions for the handling of temperature probes

- Read more: Thermocouples

Pt100 RTD sensors

The most common resistance thermometer used industrially is the Pt100-sensor. The resistance is defined to be 100 ohms at 0 °C and 138.5 ohms at 100 °C. This relation gives an approximate sensibility of 0.4 ohms per centigrade. Pt100s can be used up to about 600 °C depending on sensor designs and the standard IEC60751 gives further details.

Pt100-sensors are generally fragile compared to metal-sheathed thermocouples. By vibrating environments Pt100s should not be the first choice though there are some sensor designs that survives moderate vibrations. On the other hand the great advantage of the Pt100 is its vast stability and thus considerably more predictable properties compared to thermocouples. Also there are film resistors Pt1000 available. Their resistance at 0 °C is 1000 ohms. The sensitivity is ten times greater than that of a Pt100.

For measuring 2-, 3- and 4-wire configurations can be used. Four wires are the best configuration for accuracy reasons. Two wires should be avoided at least over one metre of length.

- Products:

- You can find our Pt100/RTD sensors on our product page: Pt100/RTD sensors

- Handling: Advice for handling temperature sensors can be found in our information sheet Instructions for the handling of temperature probes

- Read more: Pt100/RTD sensors

IR pyrometers

Unlike thermocouples and Pt100-sensors the IR-pyrometer needs not to be in contact with its object of measuring. On the other hand, IR pyrometer measures only surface temperature of the object. IR, infrared light, is electromagnetic waves that travels best in vacuum. However, it travels well in the atmosphere within some "wavelength windows" where vapour is not causing too much of radiation losses.

Industrially IR pyrometers are available for measuring within a vast range, from -50 °C up to 3000 °C, although the same individual of instrument cannot cover the complete range. The pyrometer requires optical straight-line view to the object. A variety of lenses permits measurements of various target areas.

The advantage of using IR-pyrometers is good repeatability and short response time. At constant measuring conditions the presented temperature value can be repeated in parts of a degree. The IR pyrometer is an excellent tool for comparative measurements. Alternatively, it can be used as input sensor for controllers.

IR-pyrometers are strongly dependent of the fact that the target spot emits much more radiation than it reflects radiation of the environment. This is the reason why you should avoid measuring objects with low emission and measuring nearby radiation wells, e.g. your own body. When necessary there are advanced pyrometers available which to a certain extent can overcome this problem with low emission.