Thermocouples

General information about thermocouples

The thermocouple measures the temperature difference between the probe tip and the connection to the temperature indicator terminals. Compensation for the temperature of the terminals takes place electronically in most instruments. Exceptions can be laboratories where you can maintain an ice-water bath.

The thermocouple consists in its simplest form of two wires which are joined in the measuring end. For industrial use, so-called jacket mounts are more common. Then the threads have been inserted into hard-compacted insulation material, which is usually magnesium oxide, MgO. Outside there is a metal jacket. The construction allows the jacket thermocouple to bend within certain limits and retains its geometry after completion of bending, i.e., the material is plastic.

Thermocouples with only insulated wires are used most laboriously, but there are plastics and other materials that can withstand different temperatures.

Thermocouple wire can of course also be placed in steel pipes, but this construction is mostly used at low temperatures.

At high temperatures, precious thermocouples with platinum wire must be used. Then you use ceramic rods with holes to keep the wires apart in isolation.

When the probe construction is complete, there are various ways to connect the sensor to the instrumentation. This is done for plain thermocouple types with so-called connection line and in the case of precious metal thermocouple elements, so-called compensation line is used. The former consists in principle of similar wire material as thermocouple, while the latter is so expensive that it prefers base materials that reasonably mimic the properties of the thermocouple at low temperature,

eg 0 - 100 ºC.

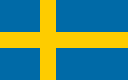

The actual connection to the thermocouple probe is shown below.

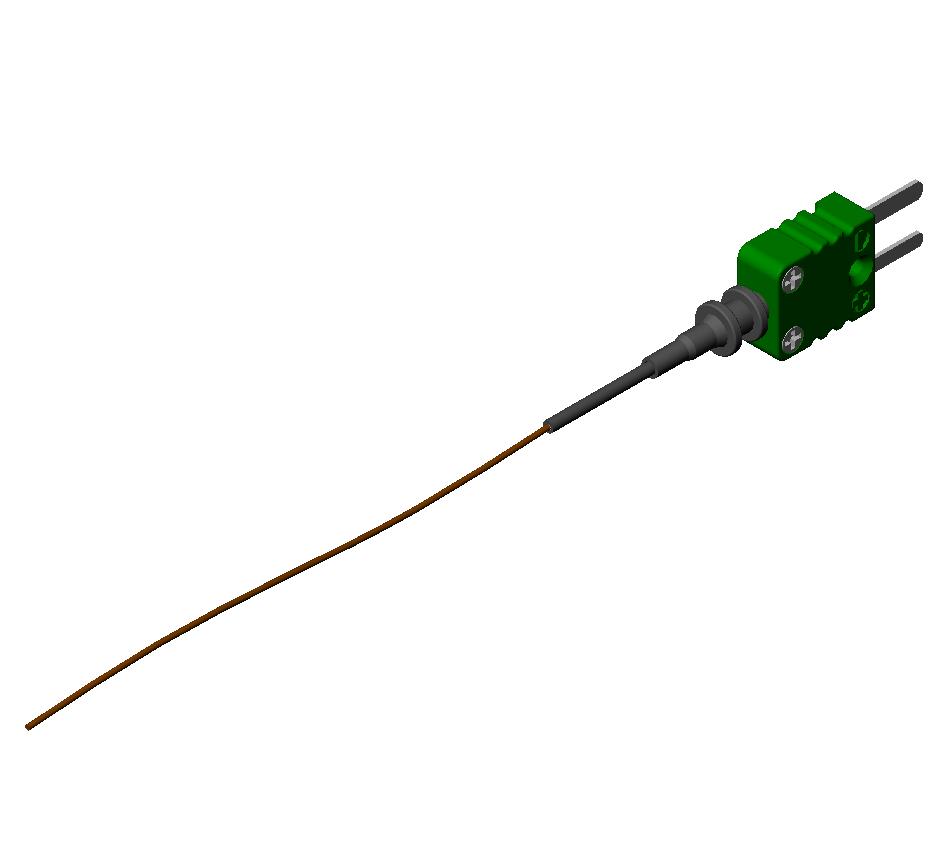

Thermocouples with connector

Mineraloxide insulated metal sheathed thermocouples (MIMS) can easily be provided with different termination connectors. There are mountable connectors available of standard size as well as miniature size. Normally male plugs are used but on request we mount female ones. See Cables and Connectors.

Thermocouples kept in store are usually supplied with moulded connectors of standard size which are completely sealed and most securely fixed to the probe.

The probes can also be ordered without connectors for later mounting on site.

The category "With connector" can also be supplied with angled probes and/or supporting tube. The supporting tube makes a thin metal sheathed thermocouple probe stronger without loss of response time. The feature is favourable in case of heavy flow rate and when compression fittings are used.

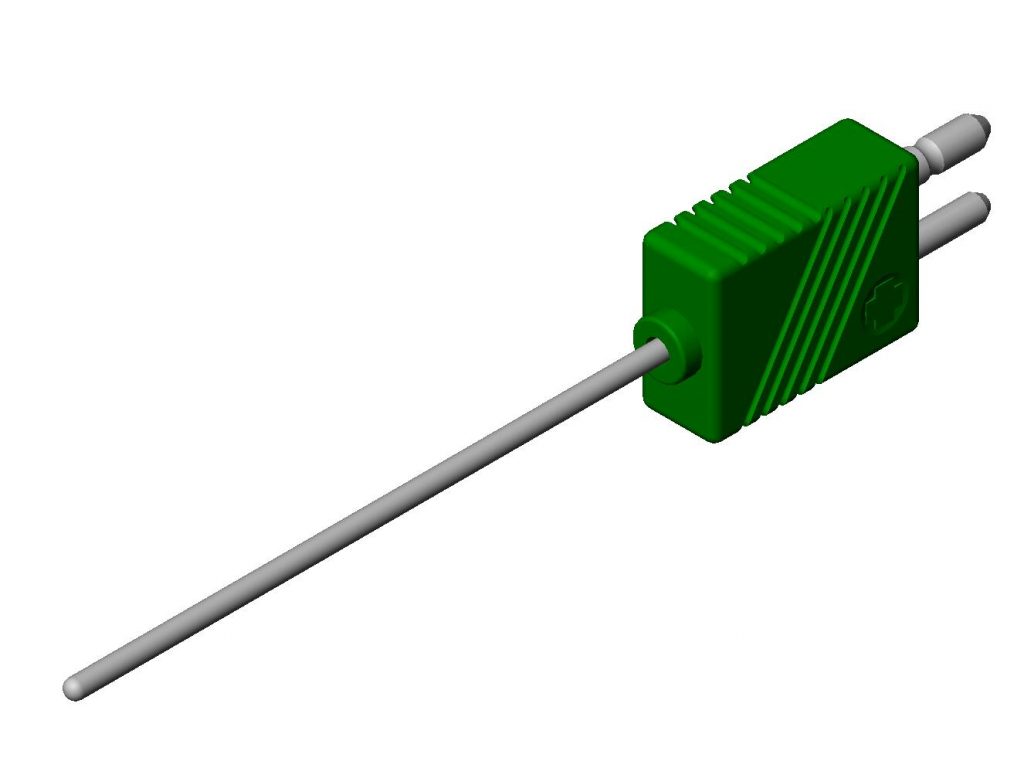

Thermocouples with cable

Metal sheathed thermocouple probes can be terminated by joining an extension cable in a transition junction. Probe and cable cannot be parted. The transistion junction is made of stanless steel and is available in three sizes to suit the diameters of probe and cable as well as holes on the way to the measuring position. The diameters of the junctions are 10 mm (standard), 7 mm (miniature) and 4 mm (sub-miniature).

Like connector terminated probes the cable terminated types can be fitted with supporting tube and be angled on request.

The extension cable can be terminated with connectors or flying leads.

Thermocouple process sensor

Thermocouple process sensors are usually characterized by signal connection in terminal heads and process connection by threads, flanges or similar. Inside the housing, there is a fixed or replaceable insertion probe terminated by a terminal block, a transmitter or in certain cases, flying leads for later choice of signal conditioning.

Pentronic keeps in stock process sensors for high temperatures with protection tubes of alloys meeting those requirements or ceramic tubing for noble metal thermocouples. Examples of use are high temperature furnaces for heat treatments and combustion furnaces. Moreover, there is a selection thermocouple sensor as alternative to Pt100 sensors, in measurement environments with heavy vibrations and shocks.

Spring loaded thermocouple

Spring loaded thermocouples normally are used to measure the bottom temperature of drilled holes, e g when moulding plastics or other melting media. A bayonet adaptor is threaded into the opening of the hole and the spring loaded bayonet cap can easily be turned to fix the sensor to the adaptor. The force of the spring secures the sensor tip to be in contact with the bottom of the hole.

Spring loaded sensors are available in designs with thermocouple wires drawn to the tip and grounded there. There are also tips with metal sheathed thermocouples making isolated measuring junctions possible. The wires can be supplied with or without protection armouring, i.e. flexible hose of stainless steel.

There are designs for fixed or continuously adjustable insertion lengths as well as straight and angled probe configurations.

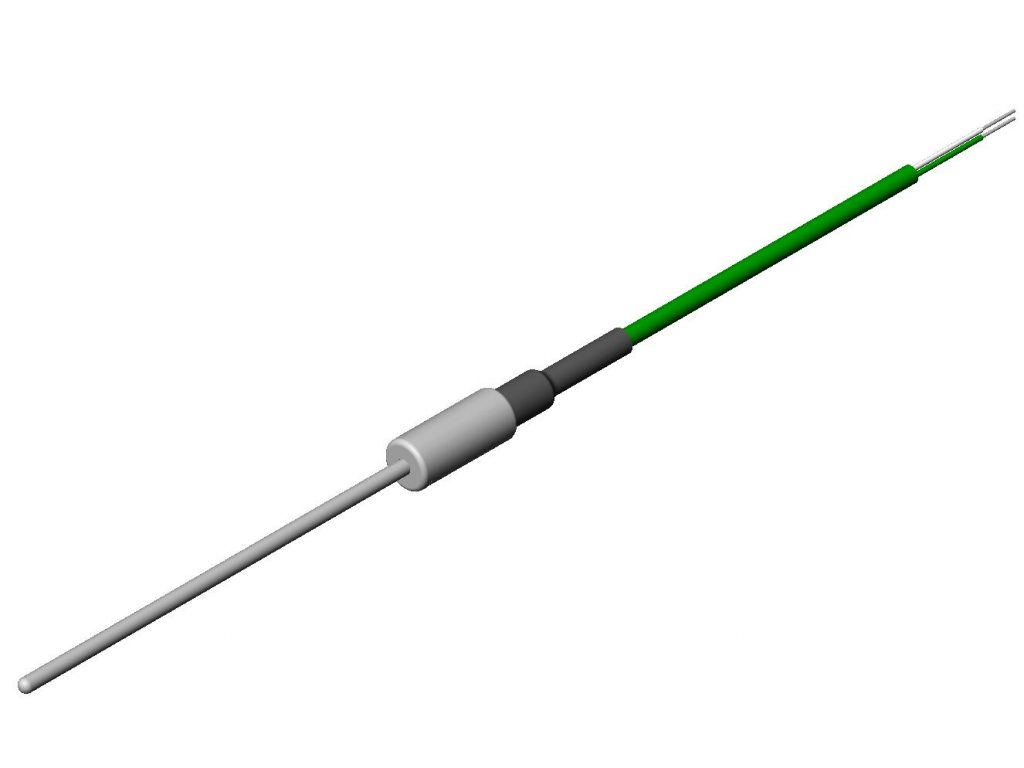

Surface measuring thermocouple

Surface measuring thermocouples are constructed with a plate surface welded to the tip of a sheath thermocouple. The sheath is then deflected so that the rest of the thermocouple is free from the surface.

The plate on the tip can be screwed to the measuring object or be clamped. Different radii of curvature can be ordered.

Thermocouple wire

Using plain thermocouple wire is a simple way of measuring low temperatures in laboratories and for testing. Thin wires gives you very short response times. Thin wires are also suitable for surface temperature measurements on e.g. metallic tubes. If the sensor is positioned between good insulation and the tube surface, you will measure temperatures very close to the flow temperature inside the tube. With no insulation you will measure the temperature of the surface.

In order to check temperatures at transportations of food it is advantageous to position the thermocouple wire between two stacked cartons to have a quick reading.

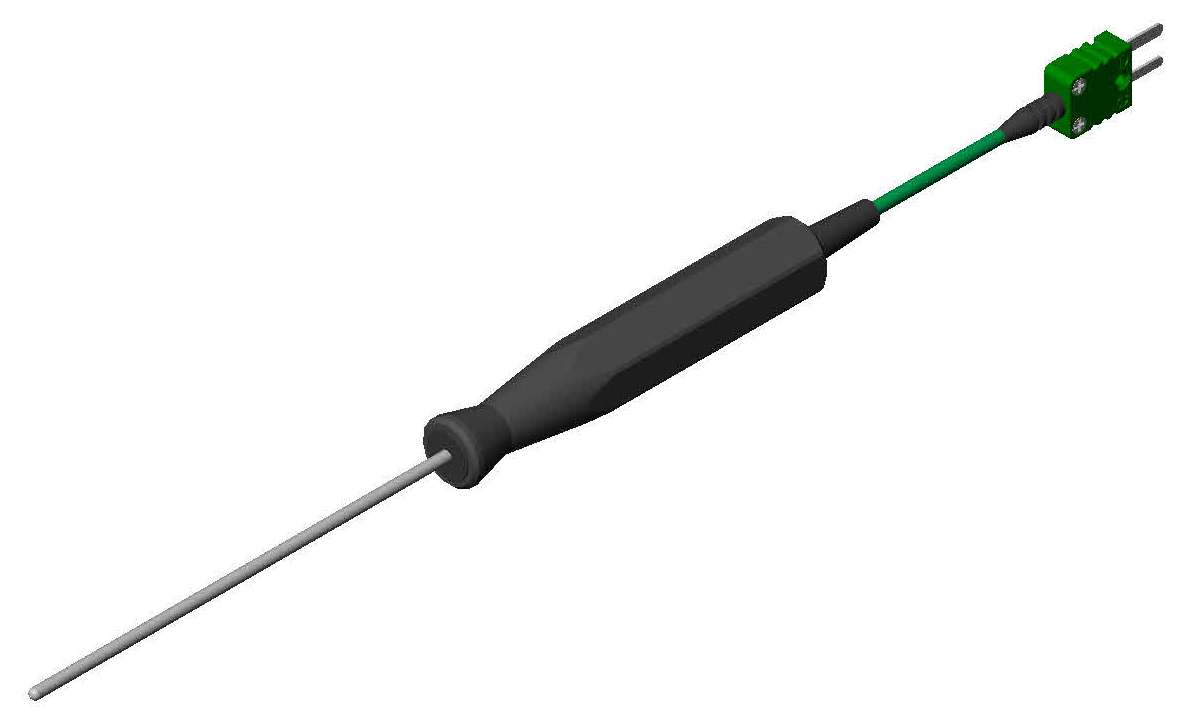

Handheld thermocouples

Pentronic markets a number of handheld temperature indicators, see Hand indicators. To those with sensor input for miniature male connector we here present some different sensor models.

Metal sheathed (MIMS) probes can very well be used in air and liquids and can with caution be used to penetrate soft and porous materials like powders.

Cannula tips are manufactured on tubular probes. Thus, these can be used to penetrate materials giving more resistance like meat and plastic packages, cartons, soil etc.

Surface temperature probes are intended for surfaces but can naturally be used in air. Liquids should be avoided.

Air temperature probes are only intended for air and non-aggressive gases.

Thermocouple engine sensors

The headline Engine sensors covers a selection of temperature sensors suited to piston engines ranging from small power sizes within the automotive and truck industries up to high power ones for power generation and ship propulsion.

Typical objects for temperature measurement are water, oil, cylinder lining, valves and exhaust.

For marine usage, sensors are available with type approvals from the common classification bodies.

Manufacturing tolerances for thermocouples

IEC is the International Electrotechnical Commission, whose standards are international and should be followed as much as possible. IEC 60584:2013

IEC 60584 was most recently revised in 2013. It incorporates reference tables and calculation polynomials for the output signals of standardised thermocouples as a function of temperature plus colour codes for identifying thermocouple type.

It also specifies tolerances for connection and compensation cables.

Tolerance should not be confused with the concept of measurement uncertainty. The properties of an individual sensor are determined by calibration.

Tolerance specifies the temperature limits from the standard-correct value of a group of thermocouples in order for them to be labelled as thermocouples of a specific type.

Thermocouple Tolerance Classes as per IEC 60584 (Reference point at 0°C)

Temperature range for thermocouples of type K, T, J, E, N, S, R, B, C and A:

The thermocouples type C and type A are new in the IEC standard. They contain different proportions of Tungsten and Rhenium as follows:

Type C: W-5%Re / W-26%Re

Type A: W-5%Re / W-20%Re

The type D: W-3%Re / W-25%Re also exists but has not been adopted by the IEC.

Note that the given tolerance figures apply to unused thermocouples. Even after very little use, changes must be assumed. Changes will be accelerated by higher temperatures and exposure to harsh environments.

Calibration of individual thermocouples or production batches at lower temperatures and in neutral environments can reduce the measuring error.